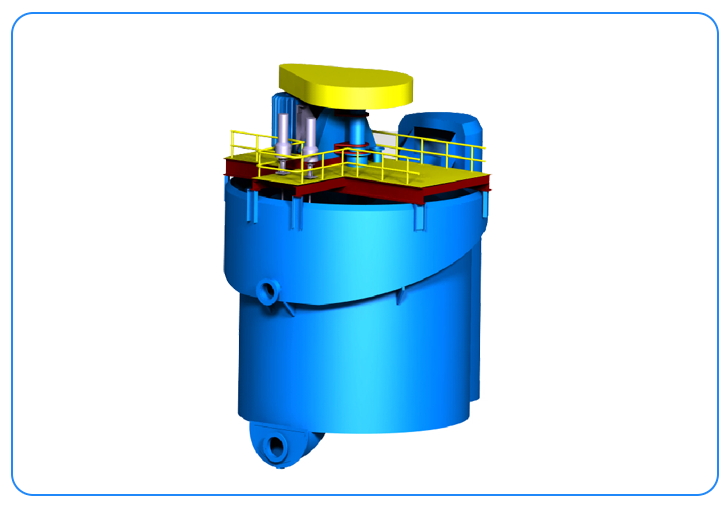

Flotation Cell

A Flotation Cell is an equipment used to carry out Flotation process, as it provides both Hydro-dynamic & mechanical conditions which will effect the separation. Creative Flotation Cell are widely used for separating non-ferrous metal, noble metal, non-metal mineral. The flotation cells achieve optimum operation through purpose designed level of solids suspension, air rate adjustment, easy froth-cone positioning and a stable pulp froth interface. The cells are used in roughing, scavenging cleaning and re-cleaning of large and middle scale floatation plants.

Benefits

- Low operating and maintenance costs

- High equipment reliability contribute to a rapid return on investment.

- The wide range of available cell sizes permits plant design to be compact, economical and efficient, without fear of short-circuiting, even for today's high tonnage operations.

- Fewer units lead to substantial savings in construction costs, piping, cables, instrumentation and auxiliary equipment

- substantial savings in construction costs, piping, cables, instrumentation and auxiliary equipment

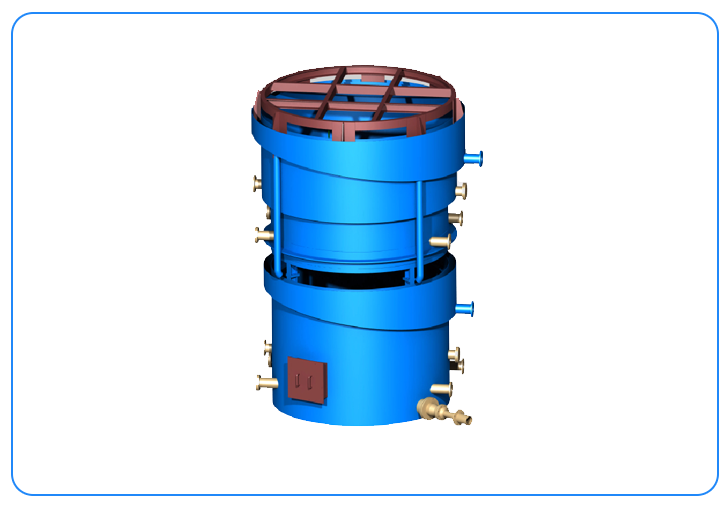

Dual extraction Flotation cell

The dual extraction column (DEC) principally resembles column flotation but differs in terms of height and bubble injection . It is a high efficiency flotation device which handles slurry feeds with wide particle size. The DEC combines low capital and operating costs. Designed for high through put with unique bubble generator to offer the advantages of low power and water usage and operates as a rougher and scavenger in one unit. The DEC is anti choking and restarts immediately after the power or plant outage. Since height of the DEC is comparatively small. it is useful to separate minerals with faster flotation kinetics.